Daim ntawv thov

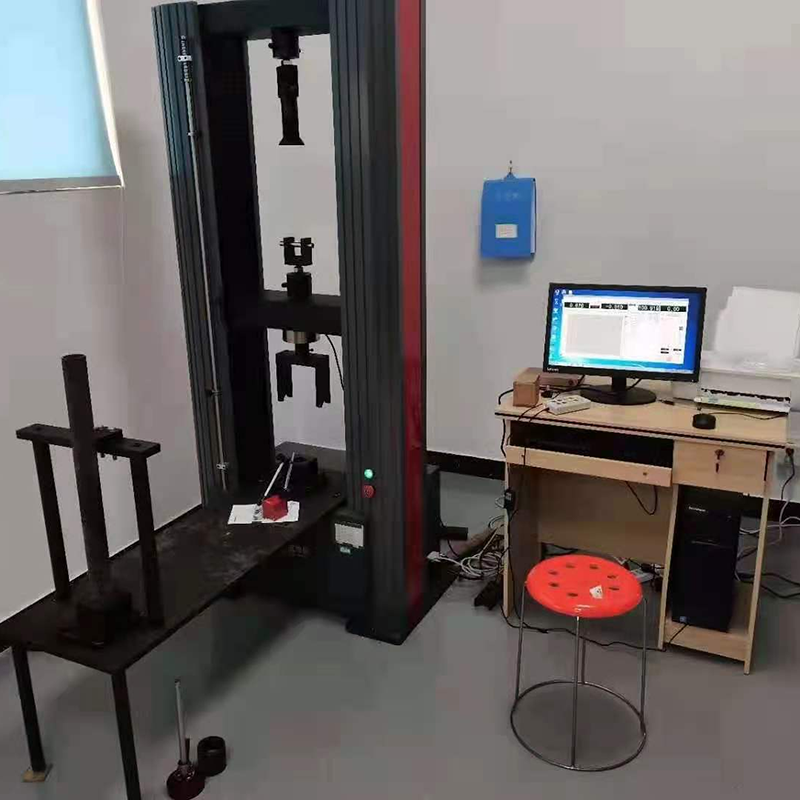

1. ZG-L series microcomputer tswj lub tais khawm thiab kev nyab xeeb net kuaj tshuab txais cov qauv tsim siab, zoo nkauj tsos, ua haujlwm yooj yim, ruaj khov thiab txhim khu kev qha.Lub khoos phis tawj ncaj qha tswj hwm lub servo ceev tswj qhov system thiab kev sib hloov ntawm servo lub cev muaj zog los ntawm tag nrho cov kev tswj hwm digital (PCI card) tsim los ntawm peb lub tuam txhab.Qhov ceev ntawm AC servo lub cev muaj zog yog decelerated los ntawm lub deceleration system thiab xa mus rau precision pob ntsia hlau khub kom paub txog lub beam sawv, ntog, xeem, thiab lwm yam. Ua kom tiav lub tensile, compression thiab lwm yam khoom ntawm cov qauv.

2. Cov kws tshaj lij software ntawm lub tshuab kuaj tau tuaj yeem tau txais cov qauv elastic, tawm lub zog, lub zog tensile, tawg lub zog, qauv elongation, nruj ntawm qhov poob siab absorbing system, tas li quab yuam thiab deformation, tas li deformation thiab quab yuam thiab lwm cov ntaub ntawv thiab cov ntsuas, uas muaj peev xwm ua tau raws li qhov kaw-voj tswj hom kev hloov pauv tsis tu ncua, qhov kev ntxhov siab tsis tu ncua thiab deformation tsis tu ncua, thiab cov txheej txheem kev sim tuaj yeem raug programmed thiab tswj tau raws li tus qauv xav tau.Kev tswj thiab kev ua cov ntaub ntawv ntawm cov txheej txheem xeem los ntawm lub computer tswj system ua tau raws li cov kev cai ntawm lub teb chaws cov qauv rau cov ntaub ntawv hlau thiab cov ntaub ntawv uas tsis yog hlau, thiab cov ntaub ntawv xeem muaj ntau haiv neeg xws li WORD, EXECEL thiab lwm txoj kev.

3. Lub tshuab no tsis muaj kuab paug, tsis muaj suab nrov, kev ua haujlwm siab, thiab muaj ntau yam kev tswj ceev.Lub tshuab no tsim nyog rau kev sim cov khoom siv hluav taws xob ntawm ntau yam hlau, tsis yog hlau thiab cov ntaub ntawv sib xyaw, thiab ua tau raws li qhov yuav tsum tau muaj ntawm cov qauv hauv tebchaws.

4. Lub tshuab yog dav siv nyob rau hauv cov khoom soj ntsuam thiab tsom xam nyob rau hauv kev tsim kho cov ntaub ntawv, aerospace, machinery manufacturing, hlau thiab cable, roj hmab thiab yas, tsheb tsim, shock absorbing tshuab thiab lwm yam lag luam.Nws yog siv rau hauv kev tshawb fawb cov tsev kawm ntawv, tsev kawm qib siab, kev lag luam thiab kev lag luam mining, kev saib xyuas kev lag luam, Cov cuab yeej zoo tshaj plaws rau kev tshuaj xyuas cov khoom muag thiab kev txiav txim siab.

Specification

| 1 | Kev sim siab tshaj plaws | 100kN ib |

| 2 | Ntsuas tshuab qib | 1.0 ib class |

| 3 | Load ntsuas ntau yam | 1% ~ 100% FS (1.0 chav kawm) |

| 4 | txheeb ze yuam kev ntawm kev qhia | ± 1% (1.0 chav kawm) |

| 5 | Test quab yuam daws teeb meem | 1 / ± 500000FS (Qhov kev daws teeb meem tag nrho tseem tsis hloov pauv) |

| 6 | Kev ntsuas deformation ntau yam | 0.2% ~ 100% |

| 7 | Lub zog tswj tus nqi hloov kho ntau yam | 0.005% ~ 5% FS / S |

| 8 | Force tswj tus nqi tswj qhov tseeb | tus nqi <0.05%FS, ± 1%; tus nqi ≥ 0.05% FS, ± 0.5%; |

| 9 | Deformation tus nqi hloov kho ntau yam | 0.005 ~ 5% FS / s; |

| 10 | Deformation tus nqi tswj qhov tseeb | tus nqi ± 0.05% FS / s, ± 1%; tus nqi ≥ 0.05% FS / s, ± 0.5%; |

| 11 | Kev hloov pauv hloov pauv ntau yam | 0.01 ~ 300mm / min; |

| 12 | Displacement rate tswj qhov tseeb | ± 0.2%; |

| 13 | Tsis tu ncua kev quab yuam, tsis tu ncua deformation, tas li hloov chaw tswj ntau yam | 0.5% ~ 100% FS |

| 14 | Lub zog tsis tu ncua, tsis tu ncua deformation, tsis tu ncua hloov chaw tswj qhov tseeb | Kev teeb tsa ≥10% FS, ± 0.5% Kev teeb tsa ± 10% FS, ± 1% |

| 15 | Qhov chaw sim siv tau zoo | 400 hli |

| 16 | Qhov sib txawv nruab nrab ntawm cov kab sab saud thiab qis | 650 hli |

| 18 | hluav taws xob | 220V ± 10% 50Hz |

| 19 | Tshuab hnyav | 500 kg |

Ntsiab nta

1. Lub tshuab kuaj tsis muaj kuab paug, tsis muaj suab nrov, ua haujlwm yooj yim thiab ua haujlwm siab;

2. Lub plhaub tshuab tseem ceeb siv lub plhaub aluminium alloy, uas zoo nkauj thiab dav;

3. Lub ntsiab chav tsev yog tag nrho hauv pem teb-sawv ntsug qauv, nrog siab rigidity, ruaj khov kev ua tau zoo thiab zoo nkauj tsos;

4. Stretching thiab compression yog pom tau hais tias nyob rau hauv ob qhov chaw sib cais, zam lub tediousness ntawm hloov txawv xeem attachments nyob rau hauv tib qhov chaw;

5. Lub mainframe qauv yog ruaj khov thiab ruaj khov.Lub pob ntsia hlau tuab thiab taw qhia lub teeb ci, cov nqaj tuab thiab lub hauv paus tsim muaj lub zog nruj, uas tuaj yeem ua tau raws li qhov kev sim ntawm cov ntaub ntawv muaj zog;

6. Lub sab sauv thiab sab nqaj ntawm lub tshuab tseem ceeb thiab lub rooj ua haujlwm tau ua tiav synchronously kom ntseeg tau tias kev sib raug zoo zoo.Thaum qhov kev xeem axial tau ua tiav, txhawm rau xyuas kom meej tias qhov kev quab yuam ntawm cov qauv hauv qab ntawm lub load yog qhov cuam tshuam tsawg, thiab qhov tseeb kev ntxhov siab thiab cov txiaj ntsig tuaj yeem tau txais..

7. Cov ntsia hlau yog cov ntsia hlau hauv av precision, thiab cov ntsia hlau ntsia hlau yog ua los ntawm cov khoom siv tooj liab, uas yog hnav-resistant.Kev sib txhuam coefficient ntawm cov ntsia hlau khub me me, kev sib kis tau zoo, qhov tseeb yog siab, thiab lub zog siab;

8. Cov txheej txheem kev txo qis tsim los ntawm tus reducer, ib txoj siv sib dhos synchronous toothed, thiab lub pob ntsia hlau precision khub muaj cov qauv yooj yim los xyuas kom meej lub synchronous txav ntawm cov ntsia hlau thiab pab lub kaw lus rau nruab nrab;

9. High-power motors nrog lub zog cia, preloaded bearings, low-tension synchronous toothed bets, thiab precision pob ntsia hlau khub tuaj yeem txo lub zog khaws cia thaum lub sijhawm kuaj, kom tau txais kev xeem zoo dua thiab tau txais kev ua tau zoo dua.Nws yog qhov tseeb modulus thiab strain tus nqi.Nws yog qhov tshwj xeeb tshaj yog thaum kuaj cov ntaub ntawv muaj zog, xws li aerospace composite cov ntaub ntawv thiab hlau alloys;

10. Siv AC servo lub cev muaj zog thiab kev tswj ceev ceev los tswj cov txheej txheem kev xeem, kev tswj qhov tseeb yog siab, ruaj khov, ua haujlwm siab, tsis tshua muaj suab nrov (tsawg ceev

Yeej tsis muaj suab nrov thaum lub sijhawm).Thiab kev tswj ceev ntau yog nthuav dav heev (0.001-500mm / min), uas tsis yog tsuas yog muaj txiaj ntsig zoo rau kev ntsuas qis qis ntawm cov khoom siv niaj hnub (hlau, cement, pob zeb, thiab lwm yam), tab sis kuj rau kev ntsuas kev kub ceev ntawm Cov ntaub ntawv tsis yog xim hlau (rubber, zaj duab xis, thiab lwm yam).Nws yog qhov yooj yim los kho qhov chaw sim sai sai thaum tsis muaj kev thauj khoom, thiab txuag lub sijhawm kuaj lub sijhawm.Kev ntsuas ceev ua tau raws li qhov xav tau tam sim no rau kev ntsuas ceev ntawm txhua cov khoom siv hlau thiab cov khoom tsis yog hlau hauv Suav teb;

11. Multi-specification fixture adapters thiab ntau yam khoom siv ntxiv tuaj yeem paub txog cov khoom siv kho tshuab ntawm ntau yam khoom siv, muab cov cuab yeej ua haujlwm ntau dua;

12. Lub nplhaib concentric thiab positioning pin tag nrho ua kom lub sab sauv thiab qis coaxiality ntawm qhov kev ntsuam xyuas fixture, kom cov qauv no muaj kev ntxhov siab nyob rau hauv axial kev taw qhia;

13. Kev ntsuas quab yuam tau txais cov khoom siv high-precision hais lus load ntawm tes nrog kev ua tiav siab, siab rhiab heev thiab rov ua haujlwm zoo.Tom qab random calibration, qhov kev ntsuam xyuas tsis cuam tshuam los ntawm sab nraud quab yuam, uas tuaj yeem ua kom paub tseeb qhov tseeb ntawm cov txheej txheem kev xeem thiab cov kev txwv;

14. Lub zog kev taw qhia ntawm lub sensor yog tib yam thaum lub sij hawm tensile, compression thiab lwm yam kev ntsuam xyuas, thiab calibration thiab calibration yog yooj yim thiab yooj yim;

15. Sensors ntawm txawv specifications yuav configured raws li yuav tsum tau, uas zoo heev widens lub xeem ntau yam kom tau raws li qhov yuav tsum tau ntsuas ntawm txawv loads;

16. Qhov kev ntsuas deformation txais yuav high-precision electronic extensometer lossis loj deformation extensometer;

17. Kev ntsuas kev khiav tawm yog pom tau los ntawm kev ntsuas qhov hloov pauv ntawm AC servo lub cev muaj zog;

18. Kev nyab xeeb portable wireless tej thaj chaw deb tswj muaj tswv yim integrates ntau lub zog, uas yog heev yooj yim rau siv thiab ua hauj lwm, thiab zoo heev simplifies lub zog tam sim no configuration, txo cov kev siv ntawm discrete hluav taws xob Cheebtsam, thiab zoo txo tus nqi hluav taws xob tsis ua hauj lwm;

19. Nws tuaj yeem paub qhov kev hloov kho ceev / qeeb ntawm lub nqaj thaum cov qauv yog clamped, thiab kev ua haujlwm yog hloov tau thiab tuaj yeem hloov tau ntawm qhov xav tau;

20. Nws muaj kev ua haujlwm ntawm kev rov qab mus rau qhov chaw pib tom qab kev sim, uas ua haujlwm tau zoo thiab nrawm;

21. Nws muaj kev txwv kev tiv thaiv zoo tshaj plaws, kev tiv thaiv overload thiab overcurrent, sim tawg tsis siv neeg kaw thiab lwm yam haujlwm, txhim khu kev qha thiab nyab xeeb;

22. Nruab nrog kev ua haujlwm siab ntse ntse tag nrho-digital ywj siab tswj thiab txais yuav tag nrho-digital PID kev hloov kho kom paub txog kev kho vajtse-raws li kev coj ua piv txwv, uas tuaj yeem paub ntau yam kev kaw-voj tswj hom xws li qhov kev ntxhov siab tas li, qhov hloov pauv tsis tu ncua, thiab tus nqi tsis tu ncua.Thiab tuaj yeem paub qhov kev hloov pauv ntawm kev tswj sib txawv yam tsis muaj kev cuam tshuam;

23. Kev ntsuas thiab kev tswj hwm yog nruab nrog ntau lub luag haujlwm kuaj software pob, thiab siv VXDs high-speed data acquisition technology kom ua tiav high-speed acquisition of multi-channel data;cov txiaj ntsig kev xeem tuaj yeem txheeb xyuas thiab ua tiav raws li qhov yuav tsum tau muaj ntawm cov kev sim sib txawv, thiab cov txiv neej-tshuab sib tham sib tham txog kev tswj hwm kev ua haujlwm tau muab los pab txhawb kev sib ntxiv ntawm cov kev xeem tshiab.Txuj;Nws muaj cov haujlwm ua haujlwm zoo tshaj plaws, tuaj yeem tso saib cov kev ntsuas nkhaus thiab ntsuas cov ntaub ntawv hauv lub sijhawm, muaj qhov nkhaus zoom, duab zoom, cuam tshuam kev ua haujlwm, thiab tus cursor tom qab tso saib ua haujlwm.Nws muaj lub luag haujlwm khaws cia ntawm kev xeem nkhaus thiab cov ntaub ntawv xeem;nws muaj lub luag haujlwm ntawm ib daim ntawv xeem cov ntaub ntawv tso tawm thiab batch xeem ntawv tshaj tawm thiab luam ntawv;

24. Nrog lub network interface, nws tuaj yeem paub cov ntaub ntawv sib txuas thiab cov chaw taws teeb tswj kev ua haujlwm;

25. Cov khoom siv yog tus nqi tsim nyog.Qhov zoo ntawm cov khoom siv txawv teb chaws, tus nqi ntawm cov khoom siv hauv tsev.

Txuj

1. GB / T228-2002 "Hloov Khoom Siv Chav Kub Kub Tensile Test Method"

2. GB/15831-2006 steel yeeb nkab scaffolding fasteners

3. GB/T5725-2009 "Kev Nyab Xeeb Net"

4. GB / T15831-2006 "Steel Pipe Scaffolding Fasteners"

5. GB24911-2010 Tus qauv ntsuas lub tais-thiab-qhov ncauj fastener

6. GBT 6096-2009 kev nyab xeeb txoj siv txoj siv sia, GB 5725-2009 kev nyab xeeb net thiab lwm yam ntau pua tus qauv, thiab cov qauv txheej txheem tuaj yeem hloov kho rau cov neeg siv.