Daim ntawv thov

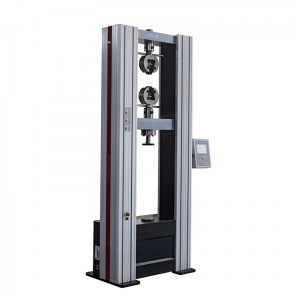

Nws yog siv rau cov khoom siv rau kev nro, compression, khoov, shearing thiab kev ntsuas qis. Haum rau cov hlau, roj hmab, yas, lub caij nplooj ntoo hlav, textile, thiab cov khoom sib piv txwv. Nws yog dav siv nyob rau hauv cov sib tham kev lag luam, kev tshawb fawb thiab kev nthuav dav, xeem chaw thiab kev kawm thiab lwm yam.

Cov kev tswj hwm database ntawm cov ntaub ntawv xeem, koj tuaj yeem siv Excel thiab lwm yam software los txuas lus nrog cov ntaub ntawv xeem; Lub tshuab muaj cov yam ntxwv ntawm cov tsos zoo nkauj, kev ua haujlwm yooj yim, ruaj khov thiab txhim khu kev qha, tsis muaj kuab paug, tsis muaj zog thiab muaj txiaj ntsig zoo.

Kev qhia tshwj xeeb

| tus qauv | WDS-200D | WDS-300d |

| Qhov siab tshaj plaws | 200kn 20 tons | 300KS 30 Tons |

| Test Tshuab Theem | 0.5 qib | 0.5 qib |

| Kuaj cov ntsuas ntsuas ntau yam | 2% ~ 100% fs | 2% ~ 100% fs |

| Tus txheeb ze yuam kev ntawm kev sim quab yuam | Tsis pub dhau ± 1% | Tsis pub dhau ± 1% |

| Tus txheeb ze yuam kev ntawm Beam Hloov Chaw | Tsis pub dhau ± 1 | Tsis pub dhau ± 1 |

| Kev daws teeb meem tsis zoo | 0.0001 hli | 0.0001 hli |

| Beam ceev hloov ntau yam | 0.05 ~ 500 hli / min (kev tiv thaiv kev hloov kho) | 0.05 ~ 500 hli / min (kev tiv thaiv kev hloov kho) |

| Tus txheeb ze yuam kev ntawm Beam ceev | Tsis pub dhau ± 1% ntawm cov nqi teev | Tsis pub dhau ± 1% ntawm cov nqi teev |

| Qhov chaw tensile zoo | 600mm Txheem Qauv (tuaj yeem ua tau customized) | 600mm Txheem Qauv (tuaj yeem ua tau customized) |

| Siv tau qhov dav dav dav dav | 600mm Txheem Qauv (tuaj yeem ua tau customized) | 600mm Txheem Qauv (tuaj yeem ua tau customized) |

| Qho loj | 1120 × 900 × 2500mm | 1120 × 900 × 2500mm |

| SERVO TSAV TSWJ | 3kw | 3.2kW |

| Kev pab fais fab | 220V ± 10%; 50Hz; 4KW | 220V ± 10%; 50Hz; 4KW |

| Tshuab qhov hnyav | 1350kg | 1500kg |

| Main configuration: 1. Muaj lub computer tshuab luam ntawv 3.. Ib pawg ntawm wedge-puab nro classs (nrog rau lub puab tsaig) 5. Ib txheej ntawm compression clamps | ||

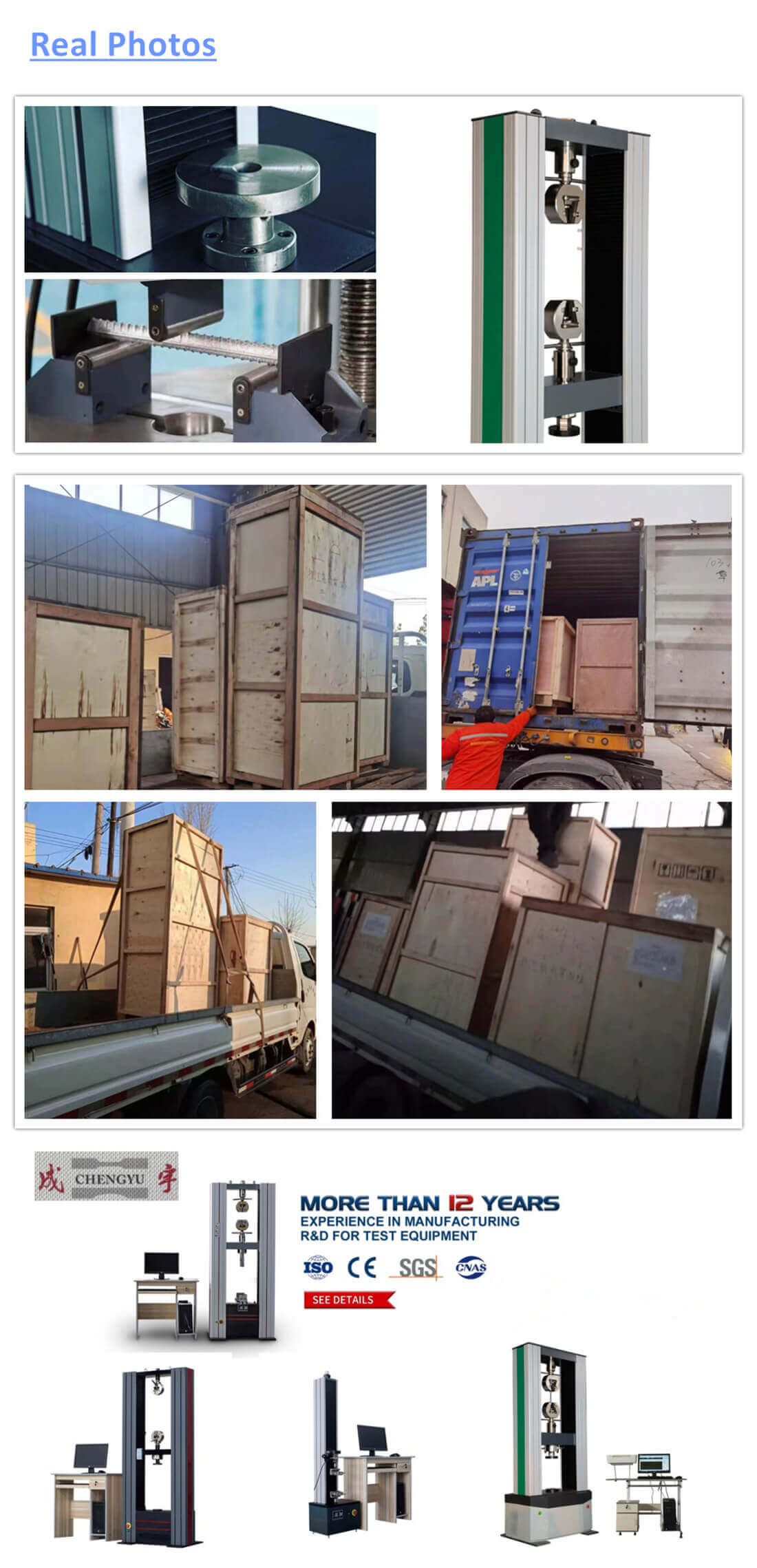

Cov Nta Tseem Ceeb

1. CAPT PARDS, HAND HEEV, qis rau compression, sab saud rau tensile, qis rau compression, ob chav. Cov nqaj yog kauj ruam tsawg dua li kev nqa khoom.

2. Txais pob ntsia hlau tsav, pom tias tsis muaj kev tshem tawm kev sib kis, nco ntsoov qhov kev tswj hwm qhov kev ntsuas thiab deformation ceev.

3. Lub phaj shiel nrog txwv cov txheej txheem siv los tswj lub nqaj txav tau ntau yam vim kev txav mus deb heev.

4. Lub rooj, txav cov kab teeb tsa yog ua los ntawm cov khoom ua kom zoo precision macherry hlau phaj, tsis tsuas yog txo qis qis dua.

5. Peb txhua kab ntawm cov kev taw qhia uas yuav tsum tau ua, ua rau lub tsev tseem ceeb ntau ntxiv txhim kho, kom paub ntxiv kom ua tau qhov kev ntsuas ntawm kev ntsuas.

6. Txais cov pob tw ntaus pob type nyem teeb, ua rau tus tuav hloov yooj yim dua.

7. Txais AC Servo tsav tsheb thiab AC servo lub cev muaj zog, nrog kev ua tau ruaj khov, txhim khu kev qha ntau dua. Muaj ntau dua-tam sim no, tshaj-voltage, over nrawm, ntau dhau kev tiv thaiv ntaus ntawv.

Lub hom phiaj

ASTM, ISO, DIN, GB thiab lwm tus qauv thoob ntiaj teb.